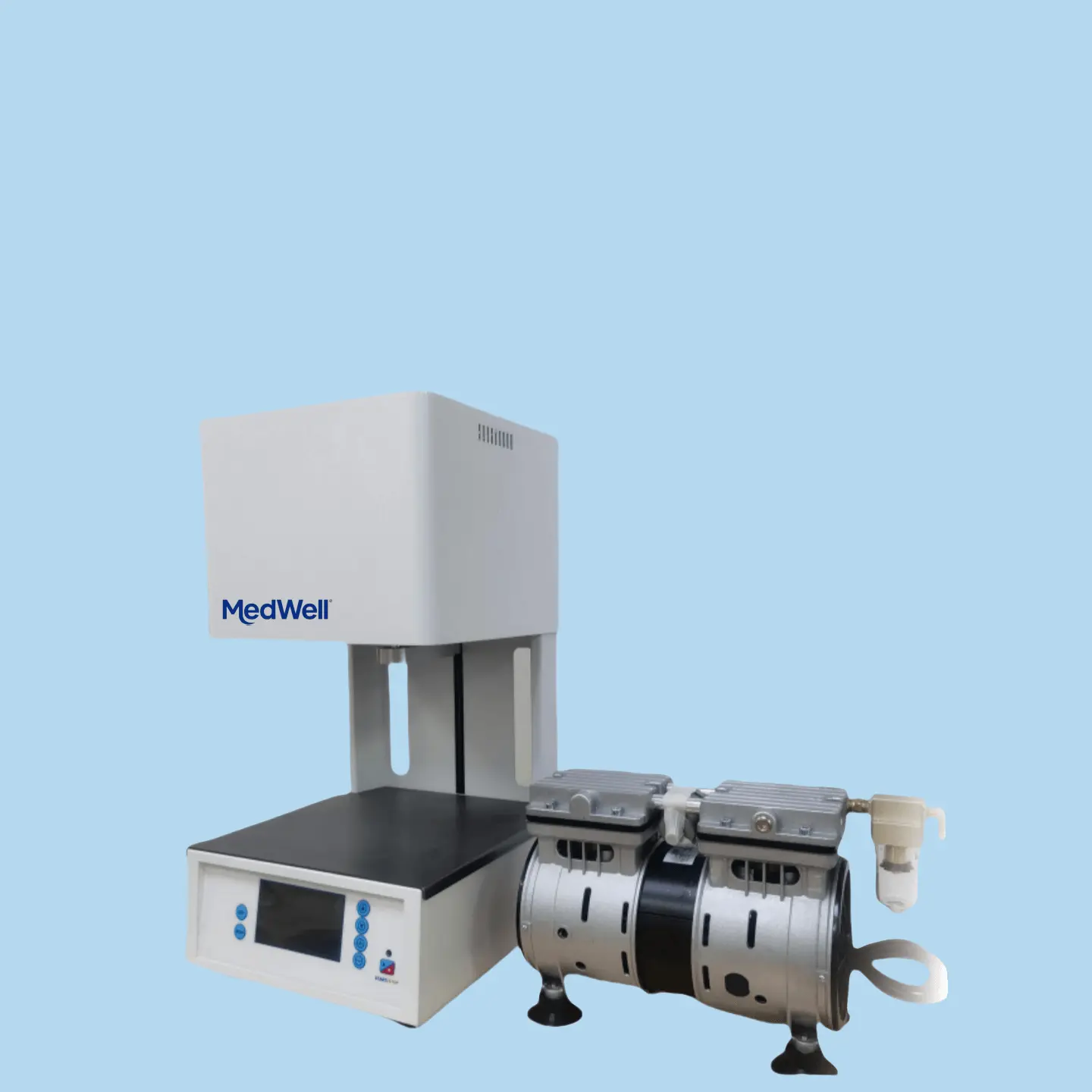

Dental Furnace

Advanced Sintering and Firing Solutions

State-of-the-art sintering furnace designed for precision ceramic processing. Our advanced heating technology ensures optimal firing results for various dental materials with exceptional temperature control and efficiency.

Rapid Sintering Technology

Advanced 4 Silicon Molybdenum Rod Ring-Shaped Heating System

Advanced Heating Performance

Rapid Sintering

4 silicon molybdenum rod ring-shaped heating, fast heating speed, precise temperature control inside the furnace, and the fastest sintering can be achieved in about 2 hours.

Easy to Operate

Customized language, full touch screen display, clear program, temperature, and time.

Pre-set Programs

Pre-set with 30 heating curves, one-button sintering.

Compact Design

Compact and stylish design with a strong technological feel, suitable for any setting. Low power consumption and energy efficiency, with customizable voltage settings.

Additional Features

Temperature Accuracy

±5°C precision for consistent results

Visual Monitoring

Clear view window for process observation

Safety Systems

Multiple protection features

Energy Efficient

Low power consumption design

Porcelain furnace

Specialized equipment for sintering dental ceramic materials at high temperatures to produce restorations such as dental crowns and bridges.

Precise Temperature Control

Ensures optimal firing results for ceramic materials.

Even Heating

Imported heating elements provide uniform heat distribution, preventing uneven firing of materials.

Quick Heating

Imported heating elements enable rapid heating, enhancing firing efficiency.

Safe and Reliable

Equipped with safety protection features to prevent accidents during firing.

User-Friendly

Simple interface operation, easy to use, saving time and labor costs.

Pre-Programmable

50 sintering programs available, suitable for different materials of various brands and models.

Clinical Applications

Versatile sintering solutions for comprehensive dental care

Zirconia Sintering

High-strength zirconia crowns and bridges with optimal crystalline structure

Glass Ceramic

Precise firing of glass ceramic materials for aesthetic restorations

Porcelain Veneers

Controlled firing for porcelain veneers with perfect translucency

Metal Ceramics

Precise firing cycles for metal-ceramic restorations

Implant Components

Sintering of custom implant abutments and prosthetics

CAD/CAM Blocks

Post-milling sintering of CAD/CAM fabricated restorations

Technical Specifications

Heating System

- Heating Elements: 4 Silicon Molybdenum Rods

- Configuration: Ring-shaped heating design

- Heating Speed: Rapid heating capability

- Sintering Time: As fast as 45mins

Control Features

- Display: Full touch screen

- Programs: 30-50 pre-set heating curves

- Languages: Customizable language options

- Operation: One-button sintering

Design & Efficiency

- Design: Compact and stylish

- Power Consumption: Low energy usage

- Voltage: Customizable settings

- Safety: Multiple protection features

Performance

- Temperature Control: Precise and accurate

- Heat Distribution: Uniform across chamber

- Compatibility: Multiple material brands

- Efficiency: Enhanced firing performance

Ready to Enhance Your Dental Lab?

Contact us to learn more about our dental furnace solutions and how they can improve your workflow efficiency.